Our capabilities:

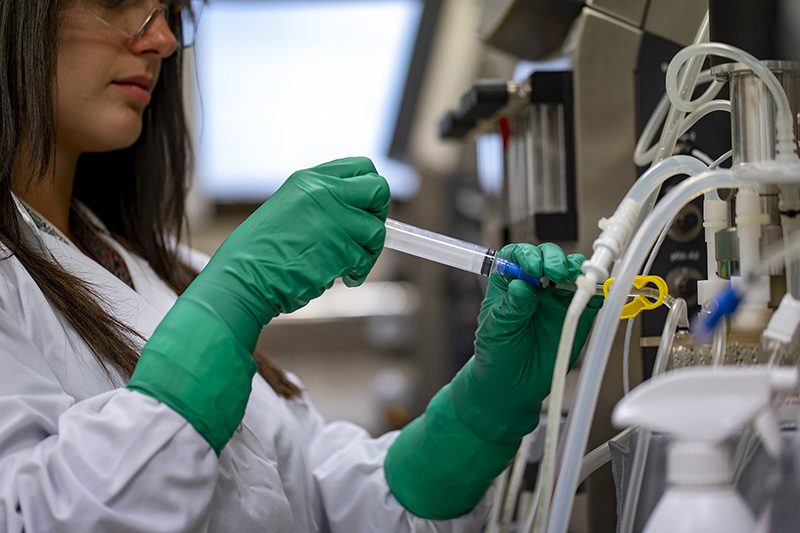

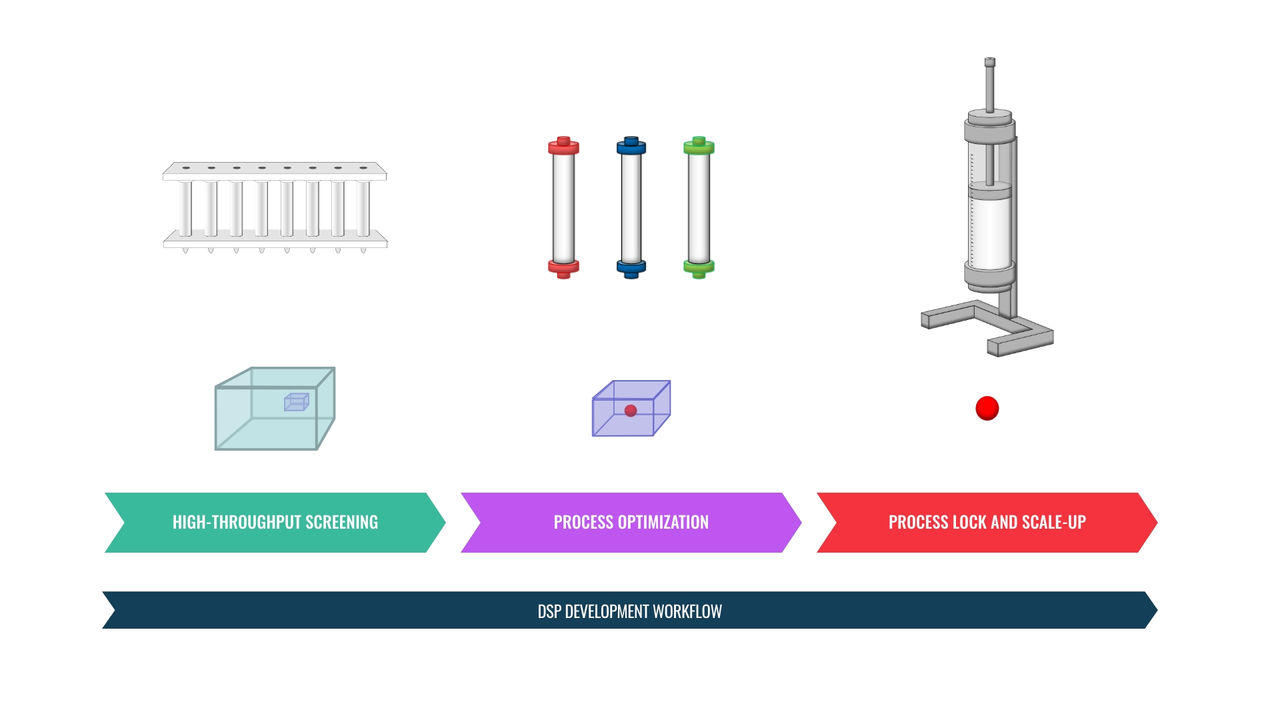

Process development

Culture media evaluation and optimisation

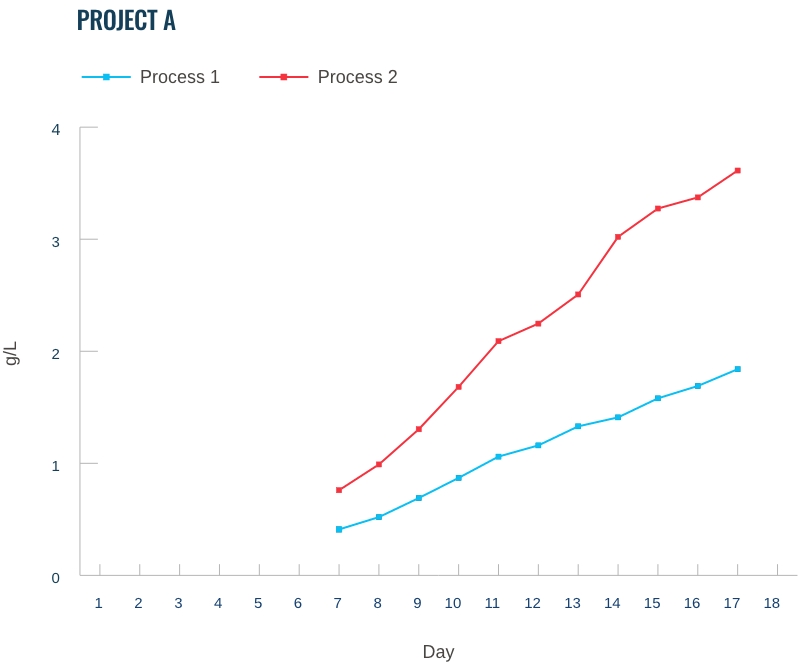

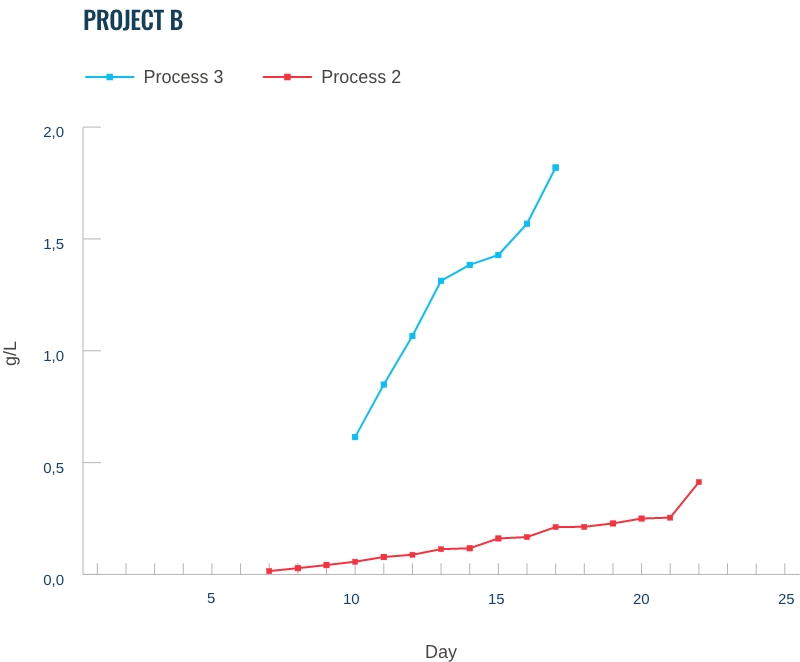

Cell line growth (duplication rate, cell metabolism and productivity) characterization and optimisation

Research Cell Bank Generation

Screening and identification of critical process parameters based on quality by design approach, with definition of process control strategies

Pre-Clinical material supply (Toxicology run)

Scale up to GMP scale

Scale down and process characterization

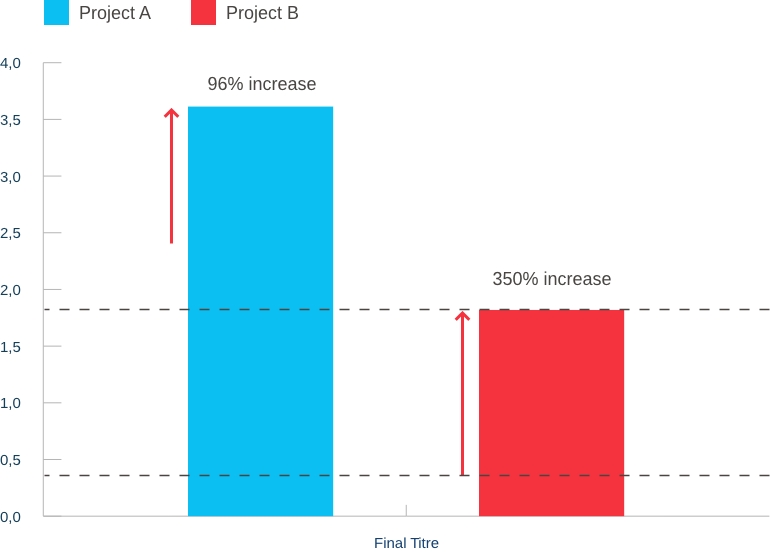

Harvest optimization to increase product yield and reduce impurities.